WP Leader: PTB

WP1: Goniochromatism

There are a variety of new goniochromatic materials which have strong angular dependent reflection behaviour. They show a colour impression that depends on the spatial arrangement of illumination and observation relative to the surface of the artefact. The goniochromatic colours are produced based on the interference effect in which the incoming light is partly reflected from the particle surface and partly refracted through it. Depending on the coating thickness and variation of the angle of incidence of the applied radiation, a colourful appearance of the reflected light at various spatial directions is produced.

So far, however, goniochromatic pigments and paints are a problem for metrology as also their colour, saturation and brightness change according to the visual perspective and the ambient lighting conditions.

Task 1.1: Improvement of the traceability for standard goniometric geometries

Start: September 2013, End: August 2015

Background: For hemispherical-directed reflectance which is measured by means of so-called integrating spheres there is an international Key-Comparison, denoted as CCPR-K5 “Spectral diffuse reflectance”. In the field of gonioreflectometry there is currently no international comparison dedicated to a set of standard geometries for directed/directed reflection.

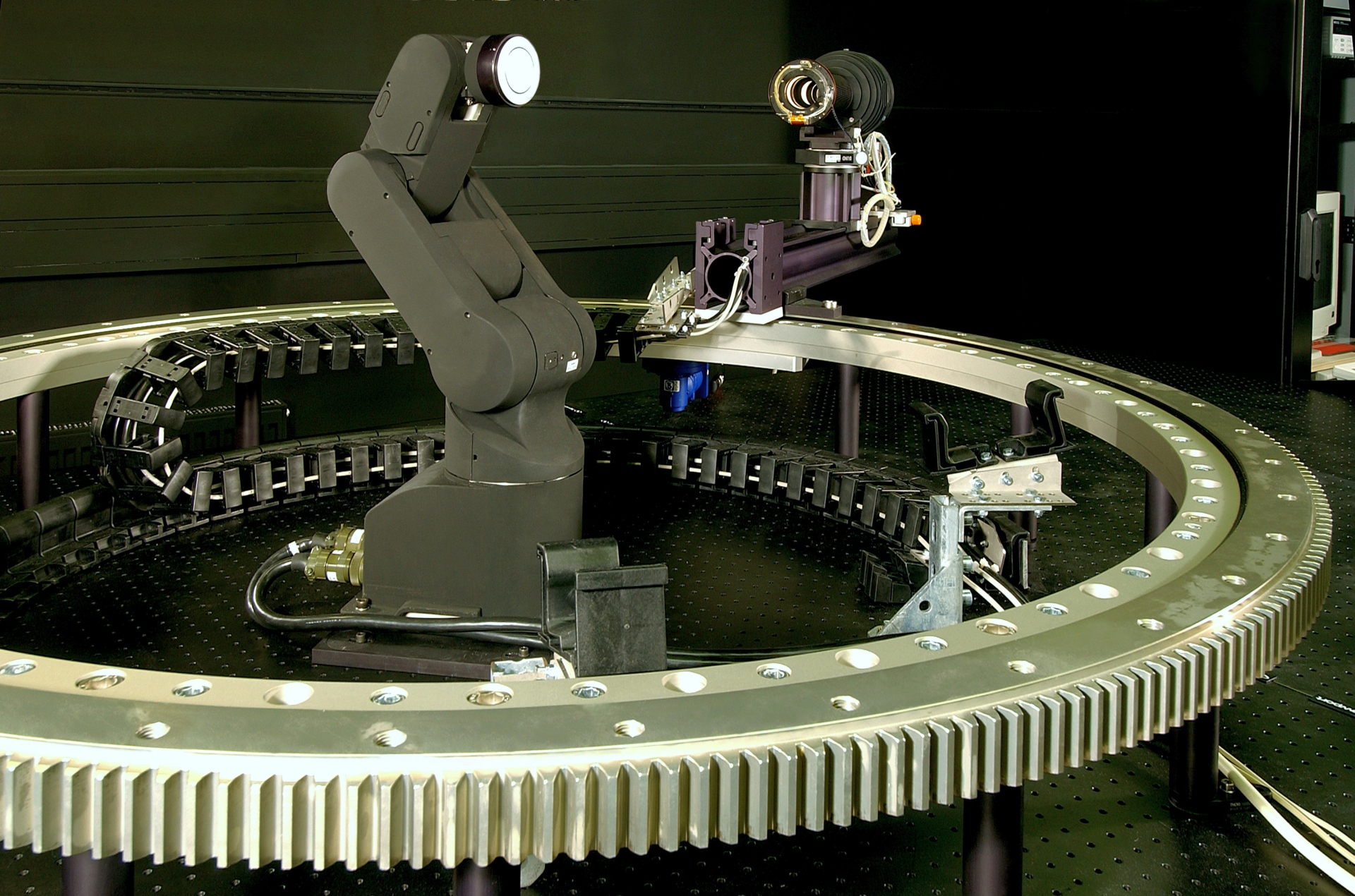

The aim of this task is to characterise existing measurement facilities of the participating JRP-Partner and REG-Organisations in order to strengthen the traceability of BRDF measurements of goniochromatic surfaces and to reduce the uncertainty of the measurement. The validation will be provided via inter-laboratory comparison of these facilities in the wavelength range 380 nm to 780 nm, the so-called V(λ)-region of visual appearance.

Description of work: We will take a first step to compare the results given by the different instruments located at institutions of the members of the consortium for a dedicated set of reflection standards (white and grey standards and also colour standards). From those results, and the measurement uncertainty budget for every instrument, uncertainties and systematic errors will be analysed (WP4).

Task 1.2: Extensive study of existing standard materials (multi-geometry, extended wavelength)

Start: September 2013, End: February 2016

Background: Industrial needs of multi-geometry reflection measurements are not limited to the spectral range between 380 nm and 780 nm where the human eye is sensitive. Relevant for industrial applications is also the neighbouring close-by spectral range between 200 nm to 2500 nm.

The aim of this task is the measurement of the angular distribution of the spectral radiance factor or the BRDF respectively of existing diffuse standard reflection materials within an extended wavelength range, exceeding the limitations of photometric applications.

The basis for the description of the angular behaviour of diffuse reflecting materials is the concept of the radiance factor β or the bidirectional reflectance distribution function fr (BRDF), respectively. Both characterisations can be traced back to the concept of the perfectly reflecting diffuser, which reflects incoming radiation lost-free, completely diffuse and with a Lambertian direction characteristics. In fact there is no such material existing corresponding to this concept. For practical reasons radiance factor measurements are predominantly accomplished relative to commercially available reflection standards. From initial studies and measurements, clear indications of strongly non-Lambertian behaviour of standard reflection materials emerged. More detailed angle-resolved reflection data within the whole half-space above the standards (so-called multi-geometry configurations) are therefore needed as important reference for manufacturers, producers and users of radiometric and photometric products.

Task 1.3: Identification of a basic set of parameters for goniometric effects

Start: September 2013, End: February 2016

Background: There is currently only one commercial instrument on the market that is measuring a quantity called “sparkle index”. The definition and basis of computation of this quantity is not revealed. Also the correlation of this index as a pure number with the sensation of the human eye is unclear. Driven by this matter of fact extensive research for an open source and traceable sparkling index is necessary.

The aim of this task is to find an irreducible set of scaling parameters for goniometric effects like lightness-flop, colour-flop or sparkle/graininess.

Task 1.4: Data handling recommendation for goniochromatic materials

Start: February 2014, End: May 2016

Background: Data processing standards for Bidirectional Reflection Distribution Function (BRDF) measurements is an important issue, since a large amount of data is obtained from such measurements. The complexity involving BRDF measurements is due to the four spherical freedom degrees to be controlled to reach every illumination/observation geometry plus its spectral dependency.

The aim of this task is to establish a formalism in which to organise and manipulate efficiently the set of data acquisitions that represent BRDF measurements in order to quickly obtain information about symmetries in the sample.

Work is also required for the standardisation of the designation of goniometric reflection geometries. Even for the commonly used “in-plane” geometries there are a variety of notations in use in different areas of industry that inhibits the efficient exchange of information. For the emerging “out-of-plane” geometries there are currently no agreed notations available.

Task 1.5: Database for impact work package (multi-geometry, wavelength dependent)

Start: September 2015, End: May 2016

The aim of this task is to create an database accessible by the scientific and industrial communities interested in goniochromatic effects. This database will contain categorised information relating to advanced surface materials, their goniospectrometric quantities and recommended measurement geometries for improved measurement traceability of their colorimetric characterisation.

Materials can be categorised by using different criteria. These criteria will be studied and selected afterward according to their relevance in industry.